-

Highlight

2300mm Paper Coating Machine

,5t Paper Coating Machine

,0.8MPa thermal paper roll machine

-

Machine Width2300mm

-

ProjectTurn Key Project

-

ConditionNew

-

Size110000*7500*7000

-

Weight5 Tons

-

Finished ProductPaper

-

Warranty3 Year

-

PackingWooden Box

-

After-sale ServiceEngineers Available

-

Voltage380V, 220V

-

CertificationCE, ISO9001, BV, ISO

-

Speed350m/min

-

FunctionPaper Coating, Chemical Coating

-

Rewind Diameter2000MM

-

Unwinding Diameter1900mm

-

ServiceEngineers Available

-

Product NamePaper Coating Machine

-

Place of OriginChina

-

Brand NameFOCUS

-

CertificationSGS

-

Model Number2300mm

-

Minimum Order Quantity1 set

-

Price800000usd per set

-

Packaging Detailswooden box

-

Delivery Time60-90 working days

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability10 sets per month

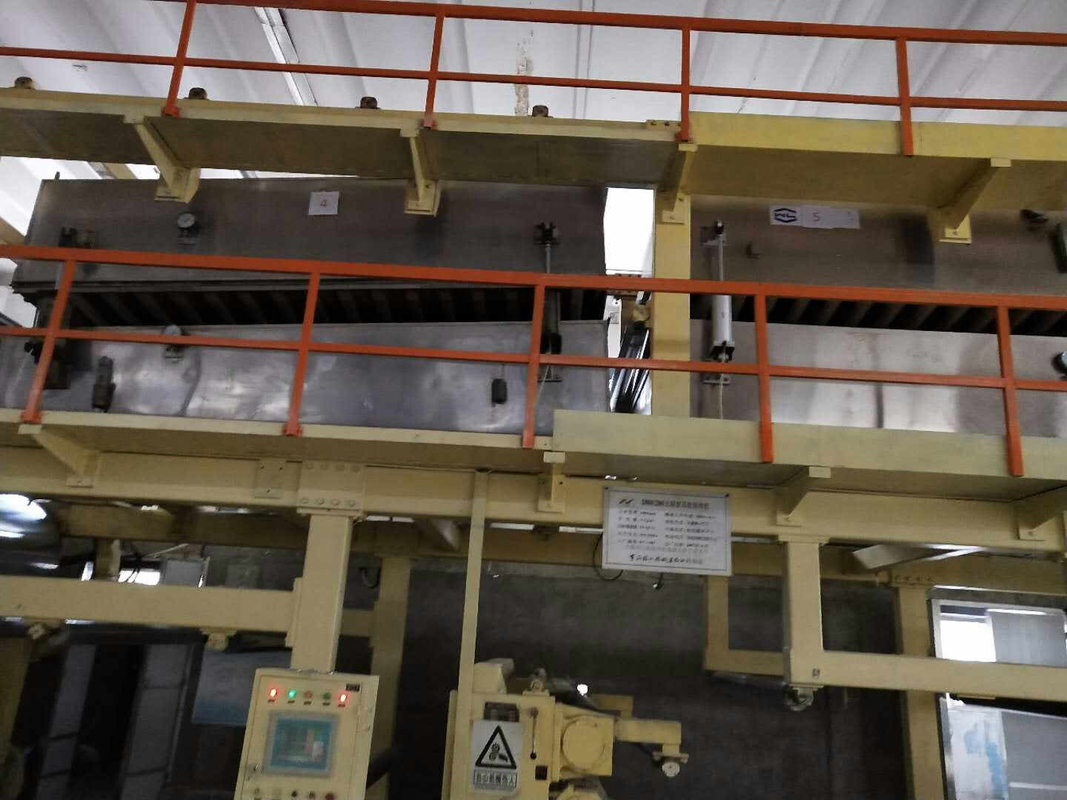

2300mm 5t Paper Coating Machine Thermal Paper Roll Machine

DESCRIPTION

FOCUS the Newest 2300mm Paper Coating Machine with Full Service

Grade: Paper board

Design speed: 400m/min

Operation speed: 300-350m/min

Max width of base paper: 2500mm

Weight of base paper: 120-360g/㎡

Coating mode: #1 Air knife coating

#2 Scraper coating

Coating weight: Air knife coater: 20-25g/m²

Scraper coater: 10-20g/m²

The coating solid content: air knife coating: 30-35%

Scraper coating: 48-60%

Driving mode: single side hot air drying

Steam pressure: heat exchanger less than 0.8 MPa

Finishing dryer less than 0.3 MPa

The compressed air pressure: 0.6 MPa

Transmission mode: frequency conversion motor sectional transmission

Total Power: 185 KW

Dimension: L x W x H = 36000mm x 7500mm x 4900mm

TECHNICAL DATA

| Items | Parameters |

| Max. Parent Web Width | 2300mm |

| Max. Parent Web Diameter | 2200mm |

| Max. Rewinding Diameter | 2100mm |

| Compress air pressure | 0.6MPa |

| Base paper weight Range | 40-250gsm |

| Max. Machine Speed | 350m/min |

| Overall dimension | 110000*7500*7000mm |

| Weight | 5000kg |

| Voltage | 220V, 380V |

GENERAL STRUCTURE

Double working position roll-over unwinding frame ( Automatic splicing device)→ No.1 Blade Combined measuring rod coater→hot air dry system (4mx3)→ Draw roll →1# Two roll calender→2# Blade Combined measuring rod coater→hot air dry system (4mx4)→ Draw roll→2# Two roll calender →3# Blade Combined measuring rod coater→ hot air dry system(4mx3)→Back water coater→Hot air dry system (4mx1) →φ1500 finishing cylinder (3 pieces)→Cold water roll→3# Two roll calendar→ Automatic splicing device→ Double working position turn over rewinding frame (automatic correction)

![]()

APPLICATION

Thermal paper after coating

Thermal Paper Jumbo Roll

Thermal Paper POS Roll

Thermal Paper Label Roll

![]()

![]()

![]()

![]()

![]()

MACHINE PACKING AND TEST RUNNING OF THERMAL PAPER COATING MACHINE

Packaging Details

The normal package is wooden box. The wooden box will be fumigated. If container is too tigher, we will use pe film for packing or pack it according to customers special request

![]()

![]()

![]()

WHY CHOOSE US

1.) Professional Siemens quality control system

2.) Simple operation

3.) High degree of automation

4.) Turn key projects

5.) More than 20 years experience

6) Double working station

7) Super Calendar

8) High capacity, low consumption

![]()

COMPANY INFORMATION

![]()

SUCCESSFUL MACHINE PROJECTS

![]()

![]()

THERMAL PAPER COATING MACHINE PRODUCTION PROCESS

CUSTOMER FEEDBACK

![]()

CERTIFICATE

![]()

FOCUS attends more than 15 exhibitions of carbonless paper/thermal paper/paper coating machine every year all over the world to meet and service clients face to face.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews