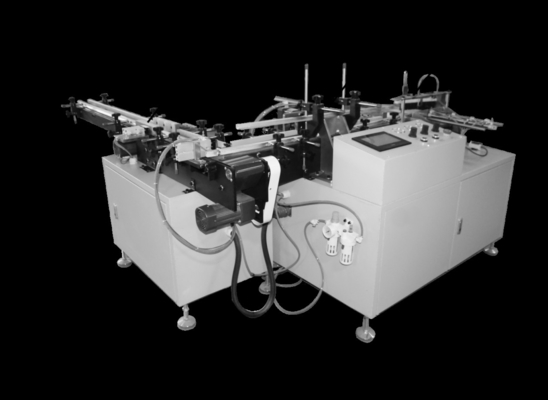

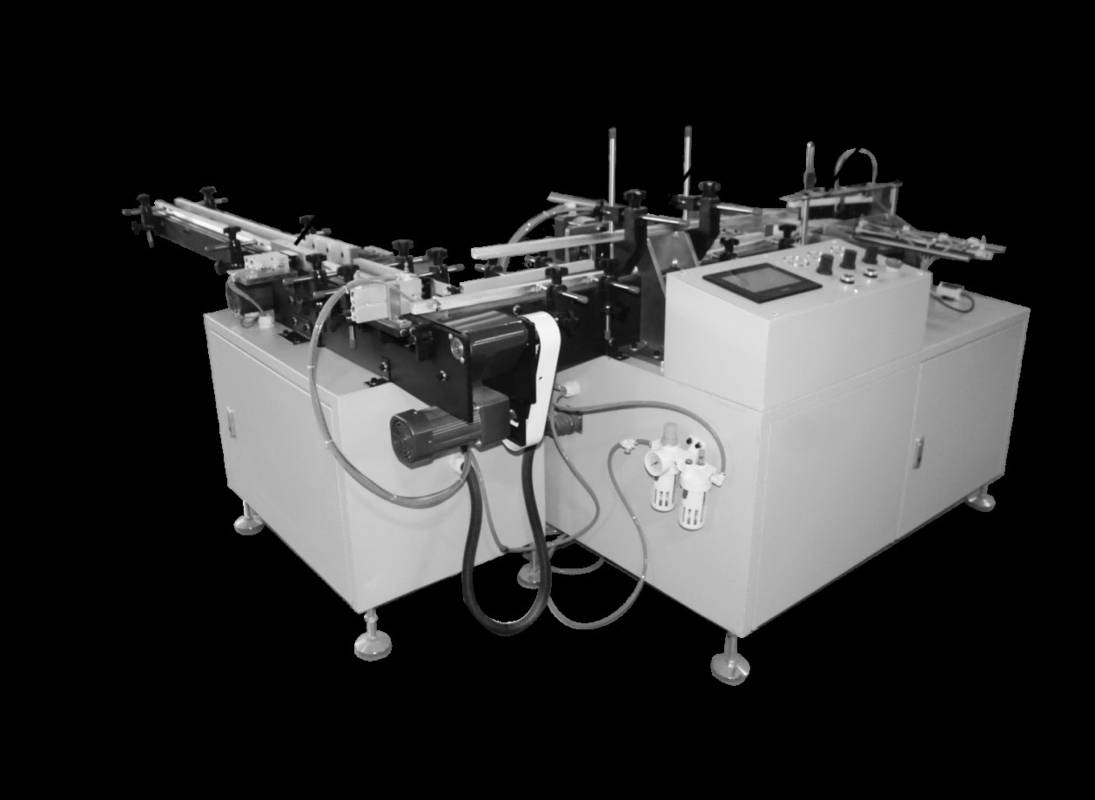

Thermal Paper Slitting Machine The Automatic Heat Shrinkable Packaging Machine

-

Model NumberFQL550

-

Current Source220V/50-60Hz

-

Rate Of Work1.5KW

-

Air Supply0.6-0.8Mpa

-

Maximum Package Size L+H(H<150mm)<600mm

-

Maximum Package Size W+H(H<150mm)<400mm

-

L * W Cutter Size670*570mm

-

Applicable Shrinkage FilmPOF/PE

-

Production Rate15-25bags/min

-

Shrinkage Ratio Of Optimal Film50%~60%

-

Table Height780mm

-

Weight (kg)350

-

Outline Dimension1900°1030*1430mm

-

Wooden Cabinet Size (length X Width X Height)1950x1100x1650mm

-

Place of OriginChina

-

Brand NameFOCUS

-

CertificationSGS, FSC,ISO

-

Model NumberFQL550

-

Minimum Order Quantity1

-

Price15000-25000

-

Payment TermsL/C, D/A, D/P, T/T

Thermal Paper Slitting Machine The Automatic Heat Shrinkable Packaging Machine

THE AUTOMATIC HEAT SHRINKABLE PACKAGING MACHINE

3.1. Main technical parameters

Paper roll diameter 30-90mm

Paper roll length 35-90mm

Transmission belt length 125mm

Breaking off speed 125 times/min(max)

Flat punching speed 125 times/min(max)

Transmission belt speed 40-500mm/s

Plastic package propelling speed 22 times/min(max)

Plastic package propelling length 30-400mm

Voltage 220V/50HZ

Machine weight 380kg

![]()

Breaking part

![]()

During cylinder operation, gently press it onto the paper roll, and the size of the paper roll can be adjusted,

Roll pushing section

![]()

Roll by breaking off the component part of the clear after the arrival of the cylinder pushroll cylinder push roll in turn roll to the flat seat to prepare the paper roll to pat flat.

Patting Part

![]()

The Roll Patting Cylinder drives the rolling plate to make reciprocating motion, and the paperolls pushed by the rolling cylinder will be flattened in accordance with the thickness, so as toprepare for the next push.

Pushing part

![]()

- Push and roll cylinder

The linear guide rail on both sides of the pusher cylinder as the pusher power soure isused as the support to improve the pusher stability.

- Detection eve

The detection eye detects that the paper roll reaches the push plate and the cylinderpushes out the paper roll.

- Paper baffle

There are many mounting holes on the roll plate and the roll baffle can be adjusted leftand right to choose the position of mounting holes to change the number of convered rolls.

- Hair brush

Just press the brush slightly against the paper roll.

Operating Specification

![]()

Parameter setting instructions

1. Flattening speed: the time for each shot of the flattened cylinder, the larger the value, the smaller the action frequency, and vice versa, the higher the frequency, the recommended value is set to 30;

2. Paper pushing speed: the time it takes for the product to be pushed from the corner to another section of the conveyor belt after breaking the paper. The larger the value, the smaller the action frequency. Otherwise, the higher the frequency, the recommended value is set to 25;

3. Paper breaking speed: the time for each breaking of the paper breaking cylinder, the larger the value, the smaller the action frequency, otherwise the higher the frequency, the recommended value is set to 30;

Key Operation Instructions

1. Package single row: package single row/double row switch;

2. Flat open: Flatten the cylinder to start the switch;

3. Flatten the switch: level the cylinder to close the switch;

4. Break the paper open: break the paper cylinder to start the switch;

5.Breaking paper off: breaking the paper cylinder to close the switch;

PLC Input/Output Point Identification Diagram

![]()

XO:Paper Pushing fiber X1:The Origin of Paper Pushing cylinder

X2:Single row pushing sensor X3:Double row pushing sensor

X4:Paper Jamming Fiber X6: Emergency stop

Y0:Roll pushing cylinder Y1:Paper Jamming cylinder

Y3:Paper Breaking cylinder Y4:Paper patting cylinder

3.4. Technical parameters of the cutting machine

| model number | FQL550 |

| current source | 220V/50-60Hz |

| rate of work | 1.5KW |

| air supply | 0.6-0.8Mpa |

|

Maximum package size L+H(H<150mm)

|

<600mm |

| Maximum package size W+H(H<150mm) | <400mm |

| L * W Cutter size | 670*570mm |

| Applicable shrinkage film | POF/PE |

| production rate | 15-25bags/min |

| Shrinkage ratio of optimal film | 50%~60% |

| Table height |

780mm (adjustable) |

|

Weight (kg)

|

350 |

| outline dimension | 1900°1030*1430mm |

| Wooden cabinet size (length x width x height) | 1950x1100x1650mm |

3.5 Name of each component

(1) operation panel

(2)Height Adjustment Handwheel

(3)shrink films

(4)Installation of shrink film devicev

(5)Retractable film fixing rod

(6)Pull film clutch handle

(7)circular shaft

(8)Systolic membrane opening triangleplate (upper)

(9)Conveying belt

(10)emergency stop switch

(11)Systolic membrane opening triangle plate (lower)

(12)Photoelectric eye

(13)Foot cup

(14)Sealing knife (upper)

(15)pulling motor

(16)Waste collection

(17)Upper seal cutter holder housing

(18)Film feeding balance rod(adjustable up and down

Operation panel

![]()

- Optional switch: Switch to manual when changing film or adjusting, switch to automatic when package running.

- Longitudinal seal temperature: Set the temperature of the longitudinal seal cutter.

- Transverse seal temperature: Set transverse seal cutter temperature.

- Sealing time: Timer setting sealing time.

- Length setting: P The product passes through the electric eye switch to the seal cutter drop, the signal light until the time set.

- Tally register: Display of product quantity.

Main Switch Instructions for Use

- Itinerary setting

The longer the time, the longer the excess part of the shrink film will be, and it will not look good after shrinking. (The post-shrinkage film of the package will cause relaxation)

Note: When the time is too short, the sealing and cutting knife is easy to cut on the product, usually 0.1-0.5 seconds (but the time is different due to the thickness of the packaging)

- Counter

The package passes through the photoelectric eye switch, and when the sealing and cutting knife descends and rises again, the number on the counter will be displayed.

*(The number on the counter is reset to zero, just press the "RESET" button on the upper right corner).

(3) Opposite photoelectric eye switch (installed on both sides of the conveyor belt)

When the package passes through the electric eye, the stroke setter works, and the sealing and cutting knife descends to seal and cut.

Run sequence

- After turing on the power switch,adjust the temperature to the appropriate temperature;However,there may be some differences due to room temperature and thickness of raw materials used Long knife 175° C, short knife 175° C, sealing time 0.8~1.2 seconds

- Adjust the width of the feed belt according to the width of the packaged object, adjust the height of the upper triangle plate to adjust the handwheel, and maintain a distance of one centimeter from the object.

- The width reservation is the distance between the stop position of the package and the center line of the transverse sealing knife. Please set it above 1/2 of the height of the WIP.

- Packaging stop time controller "belt delivery stop time ", that is, longitudinal sealing cutter center line, and packaging stop distance set at the height of 1/2.

- For packaging products at 6 cm height,please set the reserved length of raw materials

- After the width of the package is set, please install the shrink film according to the shrink film device method.

- When the sealing knife reaches the setting, pull out the raw material to end the opening into the clamping synchronous belt, press the manual control switch to seal.

- Turn on the work switch and start the conveyor belt. Products placed on conveyor belts can be automatically sealed packagin.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews