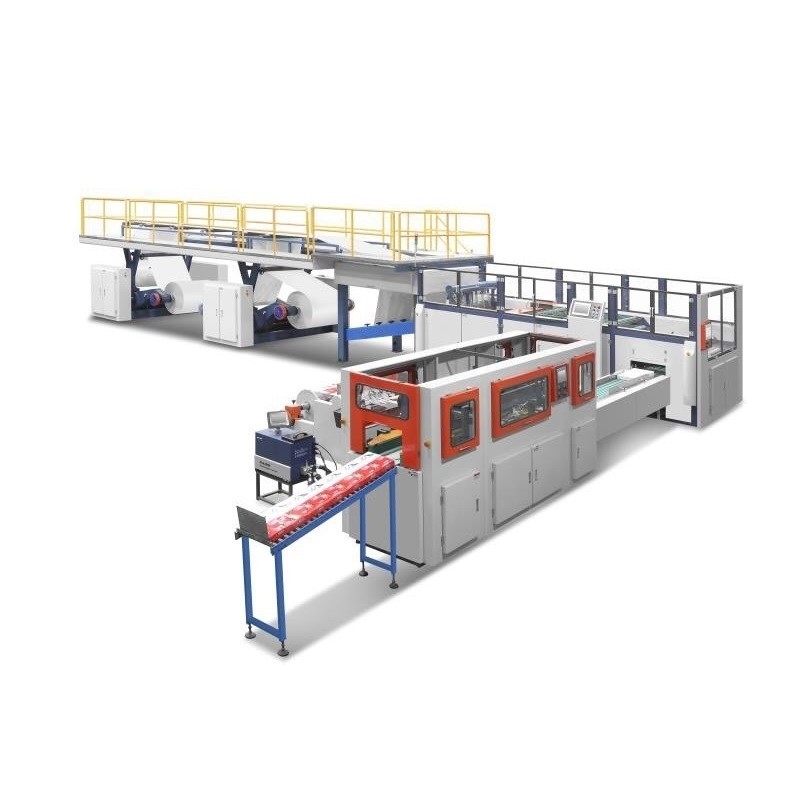

210MM A4 3in Core Paper Converting Machine 8/Min Paper Roll Slitting Machine

-

Highlight

210MM A4 Paper Converting Machine

,3in core Paper Converting Machine

,8/min paper roll slitting machine

-

Number Of Cuts5 Rolls And 5 Cuts—A4 Short Side 210mm

-

Paper Shaft DiameterMax1200mm; Min 500mm

-

Paper Core Diameter3″(76.2mm) And 6″(152.4mm)

-

Cutting LengthThe Cutting Machine Is Designed To Process A4 Paper, And Its Cutting Length Is 297mm On The Long Side Of A4 Paper

-

Paper GradeAdvanced Copy Paper, Advanced Writing Paper, Advanced Double Offset Paper And Other Advanced Papers. Paper Weight Range: 60-100g/m2×5 Sheets

-

Ream Paper Count100-500 Pages

-

Ream Paper Height65mm (max)

-

Design Speed375m/min Max

-

Weekly Discharge Of Pape8/min

-

Production Speed200-260m/min (depending On Different Paper)

-

Cutting Times650 Times/min

-

Ream Paper Discharge Weekly6-7 Times/min (28-35 Reams/min)

-

Paper Cutting Load400g/m2 (4x100g/m2) (max)

-

Paper Cutting AccuracyAllowable Error ±0.2mm

-

Paper Cutting Conditions1. The Speed Remains Unchanged 2. The Paper Shaft Cannot Be Broken 3. Qualified Paper Is Required

-

DriveAC Variable Frequency Stepless Speed Regulation

-

Main Power Supply380V 50HZ 3-phase 4-wire

-

Control Voltage220V AC/22V DC

-

Installed Capacity25KW (approm)

-

Compressed Air Consumption300NL/min (approm)

-

Compressed Air Pressure0.6-0.8 Mpa

-

Equipment DimensionsLength 20000 (mm) × Width 2960 (mm) × Height 2100 (mm)

-

Total Weight19T

-

Place of OriginChina

-

Brand NameFOCUS

-

CertificationSGS

-

Model NumberA4-35 model

-

Minimum Order Quantity1 set

-

Price1500000 usd per set

-

Packaging Detailswooden box

-

Delivery Time20-50 days

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability1 sets per month

210MM A4 3in Core Paper Converting Machine 8/Min Paper Roll Slitting Machine

FOCUS A4-35 Model Strapping Machine Hight Speed Copy Paper Roll Slititng Machine

1. Usage:

This machine is specialist for horizontal and vertical cutting paper rolling materials to A4 and other sizes etc .

2. Performance and Characteristics

1) Adopts pneumatic automatic materials loading system with much easy operation and convenience.

2) Adopts down-up recurrent cutting with orderly finished products and without water caltrop;meantime,it can be used for horizontal

cutting and vertical cutting at one time

3) It adopts servo motor for controlling constant-length cutting.

4) It adopts PLC control, contact screen operation.

5) It adopts pneumatic, displacement sensor for controlling transmission system, with photoelectric, gas

tog, it has the function of easy operation, high precision, good stability, low noise.

6) This machine has the function of the frequency converter timing device, automatic counting, stop working

by alarm ,magnetic powder tension control, can be vertically, adopt blower fan to get rid of waste.

7) It has the functions of high-precision of cutting, high speed,etc. pneumatic structure combined with

computer control be adopted for transmission section , making it become much more steady operation.

8) It has the function of automatic stacking which is in order . Photoelectric auto tracing subtense system.

Technical Data

| Main parameter |

| Working width: gross width: 1056mm; net width: 1050mm |

| Number of cuts: 5 rolls and 5 cuts—A4 short side 210mm |

| Paper shaft diameter: max1200mm; min400mm |

| Paper core diameter: 3″(76.2mm) and 6″(152.4mm) |

| Paper grade: advanced copy paper, advanced writing paper, advanced double offset paper and other advanced papers. Paper weight range: 60-100g/m2×5 sheets |

| Cutting length: The cutting machine is designed to process A4 paper, and its cutting length is 297mm on the long side of A4 paper. |

| Ream paper count: 0-500 pages, |

| Ream paper height (max) 65mm |

| Design speed: max 375m/min |

| 775 times/min |

| Weekly discharge of paper: 8/min |

| Production speed: 200-260m/min (depending on different paper) |

| Cutting times: 650 times/min |

| Ream paper discharge weekly: 6-7 times/min (28-35 reams/min) |

| Paper cutting load: (max) 400g/m2 (4x100g/m2) |

| Paper cutting accuracy: allowable error ±0.2mm |

| Paper cutting conditions: 1. The speed remains unchanged 2. The paper shaft cannot be broken 3. Qualified paper is required |

| Drive: AC variable frequency stepless speed regulation |

| Main power supply: 3-phase 4-wire 380V 50HZ |

| Control voltage: 220V AC/22V DC |

| Installed capacity: (approm) 25KW |

| Compressed air consumption: (approm) 300NL/min |

| Compressed air pressure: 0.6-0.8 mpa |

| Equipment dimensions: length 20000 (mm) × width 2960 (mm) × height 2100 (mm) |

| Total weight: 19T |

Strapping Machine

| 1. Power supply: AC380V, 50/60Hz, 1.3kW |

| 2. Machine size: L1430mm×W660mm×H1450mm |

| 3. Bundling specifications : minimum packaging size : width 150mm × height 60mm Standard frame size: 800mm wide × 600mm high |

| 4. Height of working table: 750mm (can be customized as required) |

| 5. Load capacity: 100kg |

| 6. Strapping speed: ≤2.5 seconds/track |

| 7. Tightening force: 0-60kg (adjustable) |

| 8. Bundling form: parallel 1 to 2 channels, with photoelectric control, manual, etc. |

| 9. Table roller conveyor, can be directly conveyed when no binding is required.; Control the front and rear conveyor roller lines |

| 10. Binding strap specifications: width 9 (±0.1) mm, thickness 0.7 (±0.1) mm |

| 11. Reel specification: width 160-180mm, inner diameter 200-210mm, outer diameter: 400-500mm |

| 12. Bonding method: hot melt method, bottom bonding, bonding surface ≥90%, bonding position deviation ≤2mm |

| 13. Machine weight: 330kg |

| 14. Noise: In the working environment, the noise is less than or equal to 80dB (A) |

| 15. Environmental conditions: humidity ≤90%, temperature 0-40℃ |

![]()

MACHINE PACKING AND TEST RUNNING OF THERMAL PAPER COATING MACHINE

Packaging Details

The normal package is wooden box. The wooden box will be fumigated. If container is too tigher, we will use pe film for packing or pack it according to customers special request

![]()

![]()

![]()

WHY CHOOSE US

This machine has the features of simple operation and high degree of automation. All parameters are adjusted to the best condition before leaving the factory. The only thing you need to do is to input the data of speed and tension, then the whole machine can be automatically and simultaneously controlled. It becomes more and more popular all over the world.

1) Professional Siemens quality control system

2) Simple operation

3) High degree of automation

4) Turn key projects

5) More than 20 years experience

6) Double working station

7) Super Calendar

8) High capacity, low consumption

![]()

![]()

COMPANY INFORMATION

![]()

SUCCESSFUL MACHINE PROJECTS

![]()

![]()

THERMAL PAPER COATING MACHINE PRODUCTION PROCESS

![]()

CUSTOMER FEEDBACK

![]()

CERTIFICATE

![]()

FOCUS attends more than 15 exhibitions of carbonless paper/thermal paper/paper coating machine every year all over the world to meet and service clients face to face.

![]()

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews