-

Highlight

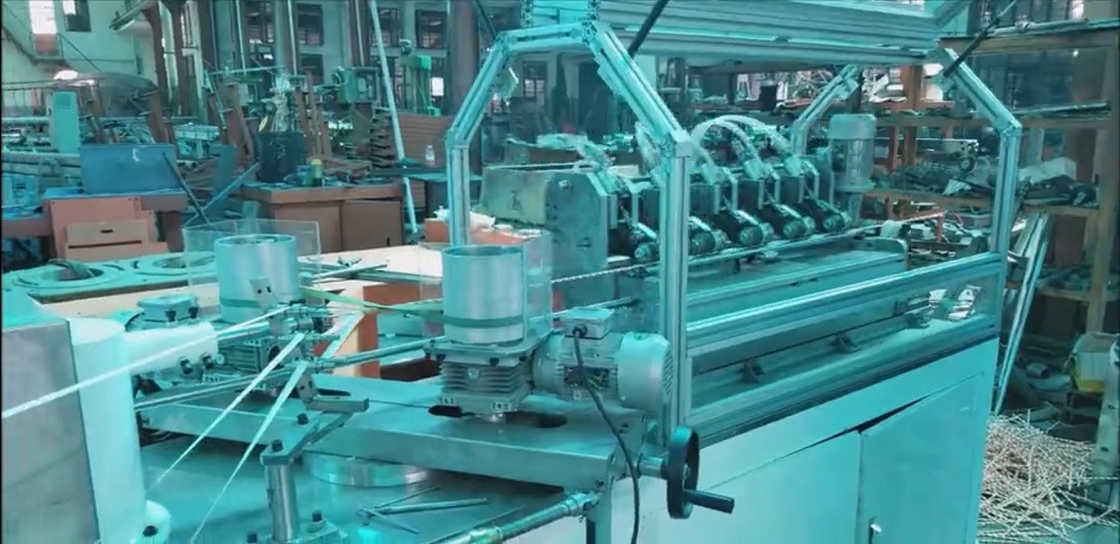

5mm paper straw making machines

,50m/min paper straw making machines

,1mm paper core machine

-

MaterialFood Grade Paper And Glue

-

Inside DiameterØ 5 Mm – 12mm

-

Thickness0.25mm –1mm

-

Speed1m/min – 50 M/min, Different Tube Size And Material Quality Lead To Different Speed

-

Cutting Length130 – 780 Mm

-

Cutting Knife7 Set

-

Place of OriginChina

-

Brand NameFOCUS

-

CertificationSGS

-

Model NumberLJ-2DXG

-

Minimum Order Quantity1 set

-

Price50000 usd per set

-

Packaging Detailswooden box

-

Delivery Time20-50 days

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability5 sets per month

5mm 50m/Min Paper Core Straw Making Machines Production Line

LJ-2DXG High Speed Paper Core Straw Making Production Line With Numerical Control

Main parts material and instruction

1. From alloy steel Moulds;

2. Durable film base Winding belt;

3. Seamless steel pipe roller wheels, surface painting with hardening treatment;

Technical Data

Operation more convenient, Because of Adopting Man-machine interface and special operating system, .

Adopt microcomputer set various parameters; Touch screen can adjustment Data conveniently.

when bottom-ply is broken, the Automatic-alarm and machine-stop system will work; Avoiding glue adheres to mandrel and causing difficult to clear away;

Packaging Details

The normal package is wooden box. The wooden box will be fumigated. If container is too tigher, we will use pe film for packing or pack it according to customers special request

![]()

![]()

![]()

WHY CHOOSE US

This machine has the features of simple operation and high degree of automation. All parameters are adjusted to the best condition before leaving the factory. The only thing you need to do is to input the data of speed and tension, then the whole machine can be automatically and simultaneously controlled. It becomes more and more popular all over the world.

1.) Professional Siemens quality control system

2.) Simple operation

3.) High degree of automation

4.) Turn key projects

5.) More than 20 years experience

6) Double working station

7) Super Calendar

8) High capacity, low consumption

![]()

![]()

COMPANY INFORMATION

![]()

SUCCESSFUL MACHINE PROJECTS

![]()

![]()

THERMAL PAPER COATING MACHINE PRODUCTION PROCESS

![]()

CUSTOMER FEEDBACK

![]()

CERTIFICATE

![]()

FOCUS attends more than 15 exhibitions of carbonless paper/thermal paper/paper coating machine every year all over the world to meet and service clients face to face.

![]()

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews